Accounting

Purchase

Sales

Orders

Inventory

Returns

Sales Force Physical Returns

Schedule a Physical Return

Capture a Physical Return and Print a Returns Checking Slip

Validate a Physical Return

Create a Distributor Credit note

Sales Force Virtual Returns

Capture a Virtual Return and Print a Returns Checking Slip

Validate a Virtual Return

Issue a Distributor Credit note and Re-Invoice

Return to Supplier

Return to Supplier (Manual)

Internal Breakages

Distributor Breakages (Replacement)

Capture a Distributor Breakage (Replacements) and Print a Return Checking Slip

Validating a Distributor Breakage - Replacement

Distributor Breakages (Credit Note)

Capture a Distributor Breakage and Print a Returns Checking Slip

Validate a Distributor Breakage (Credit Note)

Create a Distributor Breakage Credit note

Adjustments

Corrections

Products

Manufacturing

Attendance Register

Help

Additional Help

Installing Odoo as an application

Two Factor Authentication Set Up

Automated Signature

How to Register a Guest on BBB - Guest Wi-Fi

Dot Matrix printing - How to and Troubleshooting

How to Log a Support Ticket in Odoo

How to Log a New Feature request Ticket in Odoo

Sales Force

Promotion

Demotion

Pay-In Sheets

Create and print pay-in sheets pack

Register pay-in sheets

Capturing pay-in sheets

Register pay-in sheets distributor summaries

Capturing Pay-In Sheets Distributor Summaries

Create a Cosultant

Activating inactive sales force member

VoIP

Blacklisting

Suspend

Moving Consultants

Sales Force Member Information Edits

PaySpace

Contact Centre

MVNO

How to purchse data, voice, SMS and check the balance on BBB Connect HelpDoc

How to port/transfer your current SIM card number to BBB Connect SIM card

How to Recharge BBB Connect SIM card

TaskFlow

How to set up sales force meetings campaign

Making Inbound and Outbound calls for contacts 'Potential Leads'

How to create a user

How to make a sales force meeting call

How to set up extensions

How to configure sales force meetings

How to set up dispositions

How to set up a recruiting campaign

How to set up call teams

How to call the Leads and Recruits

Campaign Planner

Table of Contents

- All Applications

- Purchase

- Orders

- Local Purchase Order

- Creating a Receipt

Creating a Receipt

Introduction

Once the stock has arrived at the warehouse, The warehouse team will fill out a Delivery Slip of the counted/ Received stock, which will be signed off by the Warehouse manager and then sent to the Procurement team where the received quantity will be captured onto Odoo.

Responsible Team

- Warehouse Manager

- Receiving Personnel

- Procurement & Stock Management Clerk

- Procurement Manager

Navigation

Navigate to your Odoo dashboard and click on this application: Purchase

Navigate as follows to get to the correct screen:

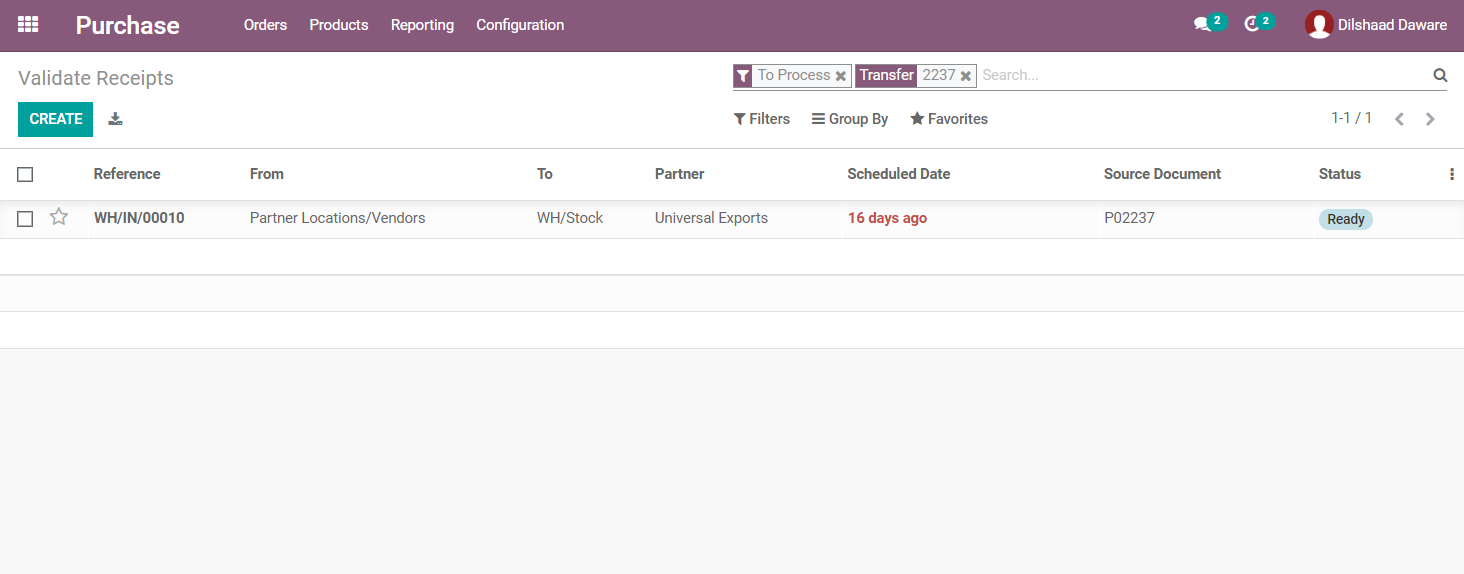

Orders/ Validate Receipts

In the search bar at the top, type in the code of the Purchase Order, you should now land on a screen that looks like this:

Process

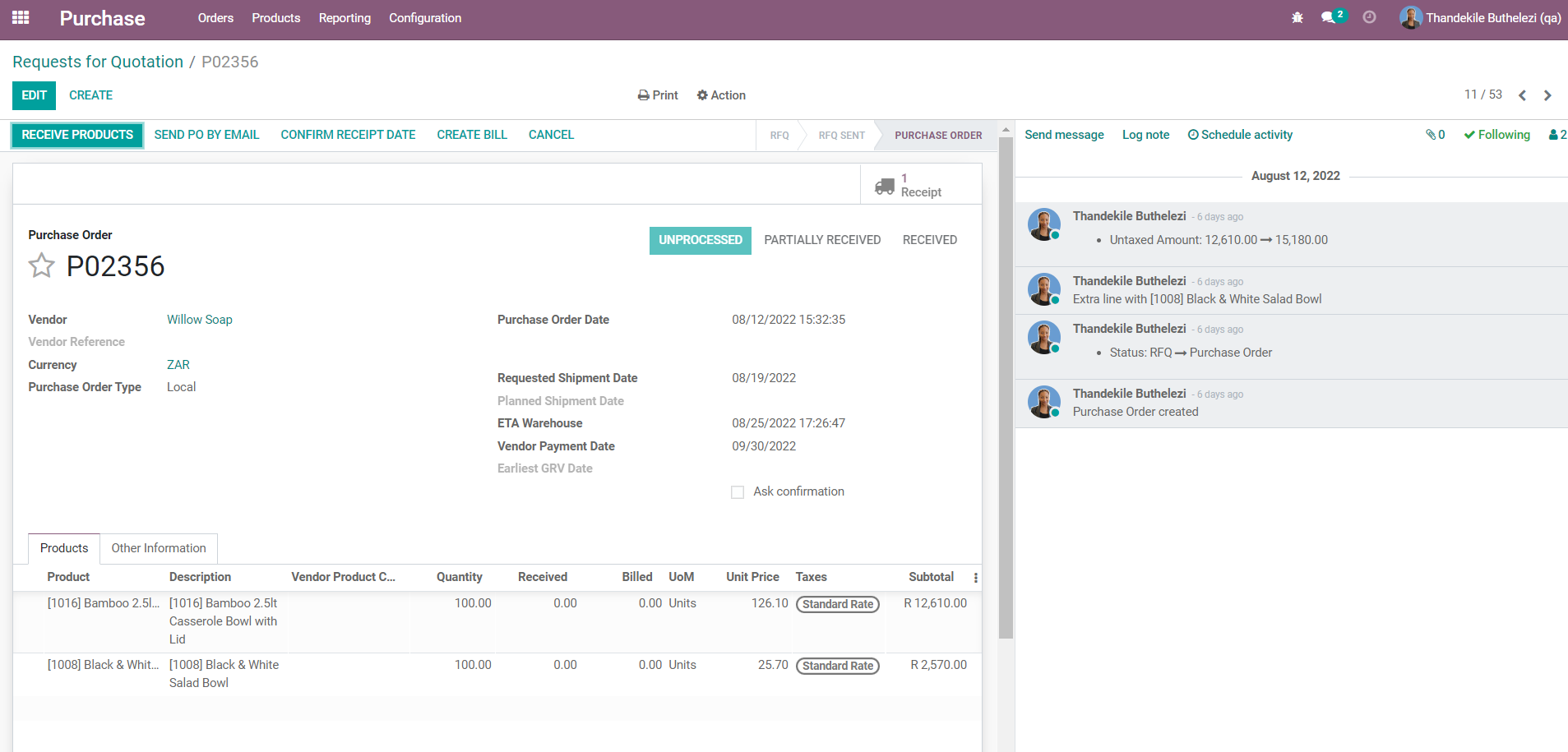

- Select the Purchase Order and click [RECEIVE PRODUCTS].

- Click [EDIT].

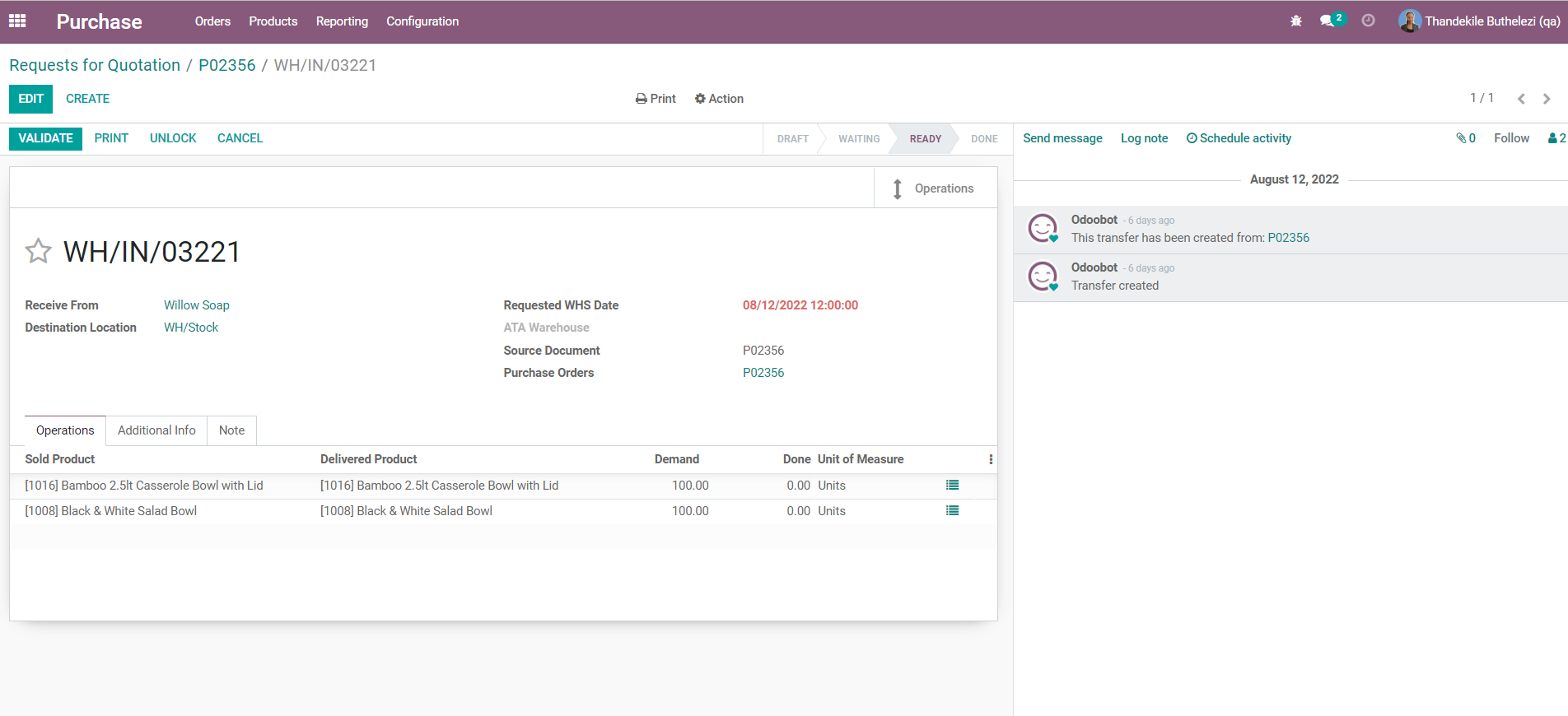

- Enter the Date of arrival under the field labelled 'ATA Warehouse'.

- Enter the received quantity under the input field Quantity according to the Blind Check Form count quantity.

- Click on [SAVE].

- Once all product quantities have been entered, click on [VALIDATE].

- The Quantity on hand values for these products have now been increased in WH/Stock on Odoo.

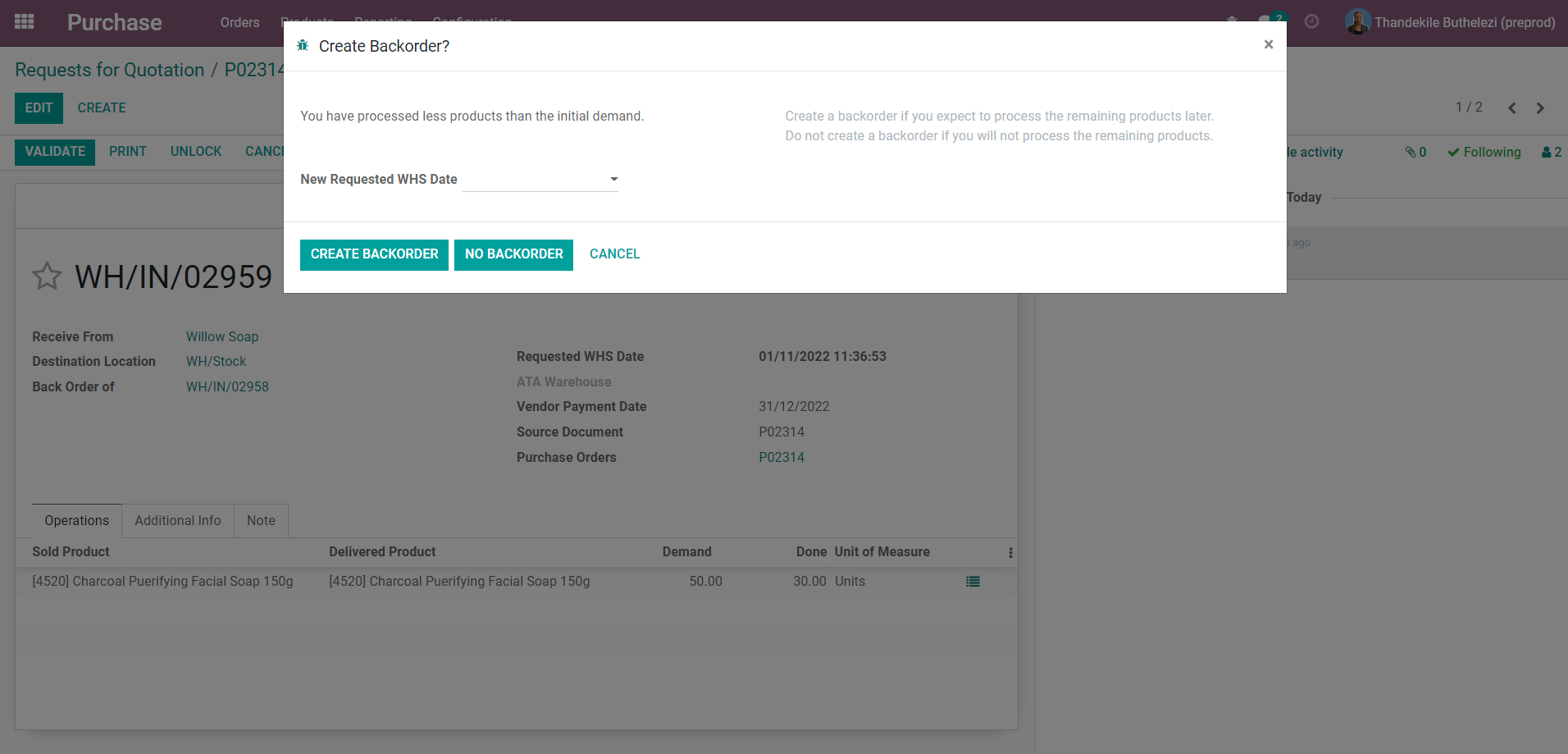

- When a user validates less stock than the ordered stock quantity, a backorder pop up screen appears asking the user to accept or decline the backorder. When the user accepts the Backorder, the following will happen:

- You will be required to enter a requested WHS date for the backorder, as shown on the screenshot below:

- Backorder Receipt will have a "Vendor Payment Date” field.

- The “Requested WHS Date” entered by the user will auto calculate the “Earliest Payment Date” using the vendor’s payment terms

- If a Receipt is not a Backorder, the “Earliest Payment date”, will be inherited from the PO Header with the same field name.

- You will be required to enter a requested WHS date for the backorder, as shown on the screenshot below:

- In an instance that the Vendor delivers a quantity lower or higher than the ordered quantity, do not change the ordered quantity to match the supplier's delivery

The weighted average cost per unit is calculated using the following formula:

When new Products arrive at the warehouse, the new average cost is computed as:

Average Cost = (Former Qty x Former Average Cost) +( Incoming Qty x Purchase+ Price) / Final Qty